| Katon® Compound | Base Polymer | Shore A (±5) | Operating Temperature | Curing System | Color | Price Range | Fluorine content % (Raw Material) |

|---|---|---|---|---|---|---|---|

| Katon® 2075B | FKM-Type 2 | 75 | -5℃~200℃ / 23℉~392℉ | Peroxide | BLACK | ★☆☆☆☆ | 68~70 |

| Katon® 1075B | FKM-Type 1 | 75 | -5℃~200℃ / 23℉~392℉ | Bisphenol | BLACK | ★☆☆☆☆ | 66 |

| Katon® 7170B | FFKM | 70 | -20℃~230℃ / -4℉~446℉ | Peroxide | BLACK | ★★★★☆ | 72 |

| Katon® 7175B | FFKM | 75 | -20℃~230℃ / -4℉~446℉ | Peroxide | BLACK | ★★★★☆ | 72 |

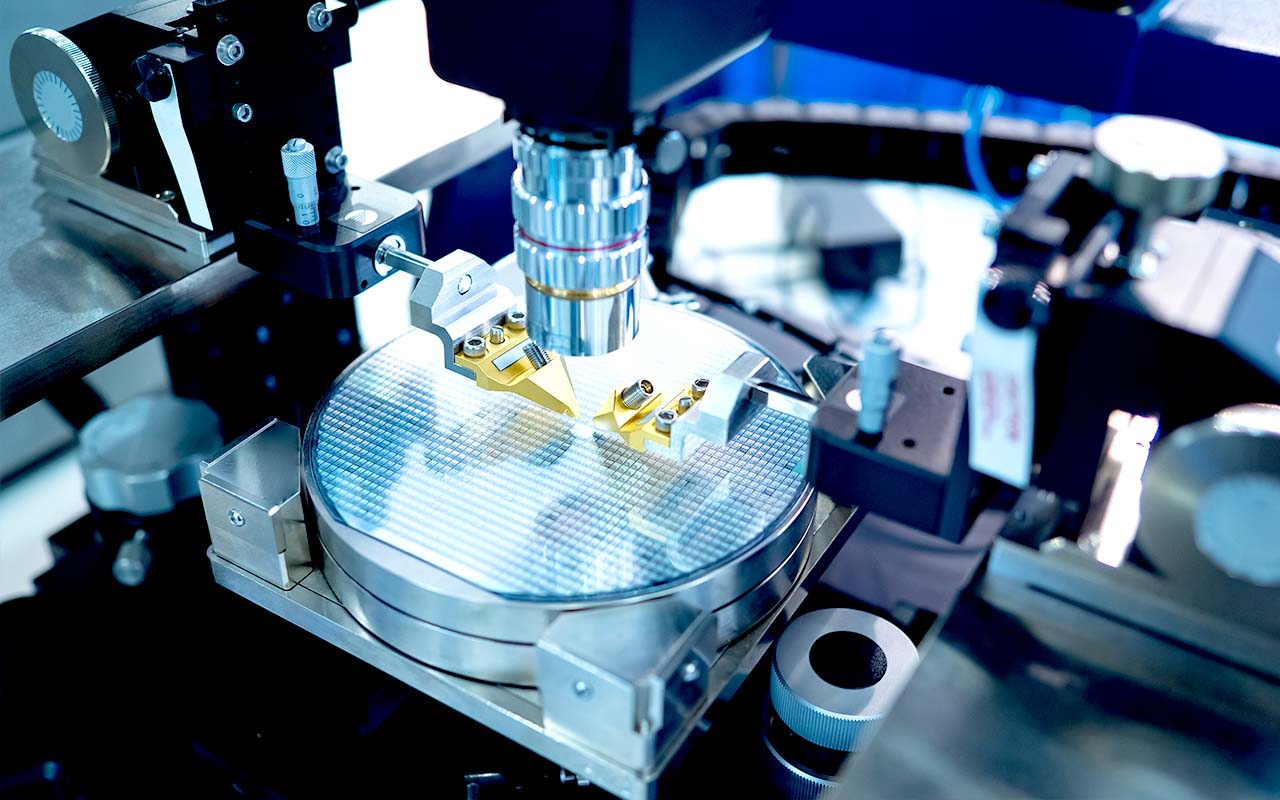

At Katon®, we understand that the electronics, electrical, and semiconductor industries require the highest standards of reliability and precision. Our sealing solutions are engineered to withstand extreme conditions and provide dependable performance, ensuring your equipment operates smoothly. Whether it's for electrical applications, engine and transmission components, exhaust pipeline seals in electronics factories, or semiconductor manufacturing equipment and clean rooms, we’ve designed our products to meet the demanding needs of these critical industries.

Applications:

- Electrical Applications: Ensuring reliable performance in high-temperature, high-pressure, and chemical environments.

- Engine & Transmission Components: Providing lasting seals that protect critical components from external contaminants.

- Exhaust Pipeline Seals for Electronics Factories: Ensuring airtight seals in exhaust systems for longer equipment lifespans.

- Semiconductor Manufacturing Equipment & Clean Rooms: Delivering clean, reliable seals to maintain process stability and precision.

(Click the side menu to choose your specific application)

These seals are designed to withstand extreme conditions, including high heat, corrosive chemicals, and plasma exposure.

Offering exceptional chemical compatibility, thermal resistance up to 200-230°C, and low outgassing, they ensure reliable sealing in highly sensitive operations.

- Superior resistance to high temperatures

- Enhanced plasma resistance

- Excellent chemical compatibility, including resistance to acids, solvents, and organic and inorganic compounds

- Acidic gases in semiconductor exhaust systems.

- Hydrocarbons and fluorinated fluids in electronics manufacturing.

- High-temperature amine-based compounds and nitro hydrocarbons (e. g., nitrobenzene, aniline).

- Environments with ketones (e. g., MEK).

- Exposure to halogenated refrigerants or brake fluids.

- Applications involving steam, hot water, polar solvents, or low molecular weight organic solvents.

At Katon®, we are committed to providing more than just high-quality O-Rings. We offer a complete customer experience from start to finish. Our services include:

- Expert Consultation: Our team of engineers and product specialists work closely with you to understand your specific needs and provide tailored solutions.

- Custom Solutions: We offer flexible options for custom sizes, materials, and configurations, ensuring a perfect fit for your unique applications.

- Fast Turnaround: With our advanced manufacturing capabilities, we ensure quick production and delivery times to meet your project deadlines.

- Technical Support: Our dedicated support team is always ready to assist with material selection, application advice, and troubleshooting.

- Global Reach: Katon® serves industries worldwide, with a commitment to delivering reliable, cost-effective sealing solutions to customers across different sectors.

Whether you’re looking for standard O-Rings or specialized custom seals, Katon® is here to help you find the right solution, every time.